Unlock Cost Savings: 8 Proven Strategies to Manage Inventory Costs

Managing inventory costs efficiently is crucial for business profitability. Explore 8 proven strategies to optimize inventory management and reduce costs.

Efficient inventory management is at the heart of any successful business. When done right, it ensures that you have the perfect amount of stock on hand while slashing operational costs, boosting profitability, and keeping customer satisfaction high. However, poor inventory practices—such as overstocking, stockouts, or outdated inventory—can drain resources, disrupt cash flow, and jeopardize your bottom line.

Whether you’re a small retailer or a large-scale manufacturer, managing inventory costs effectively is crucial for long-term success. In this article, we’ll break down eight actionable strategies to help you streamline your inventory processes, optimize resources, and maintain a competitive edge. By mastering these techniques, your business can achieve the ideal balance between meeting customer demand and controlling expenses.

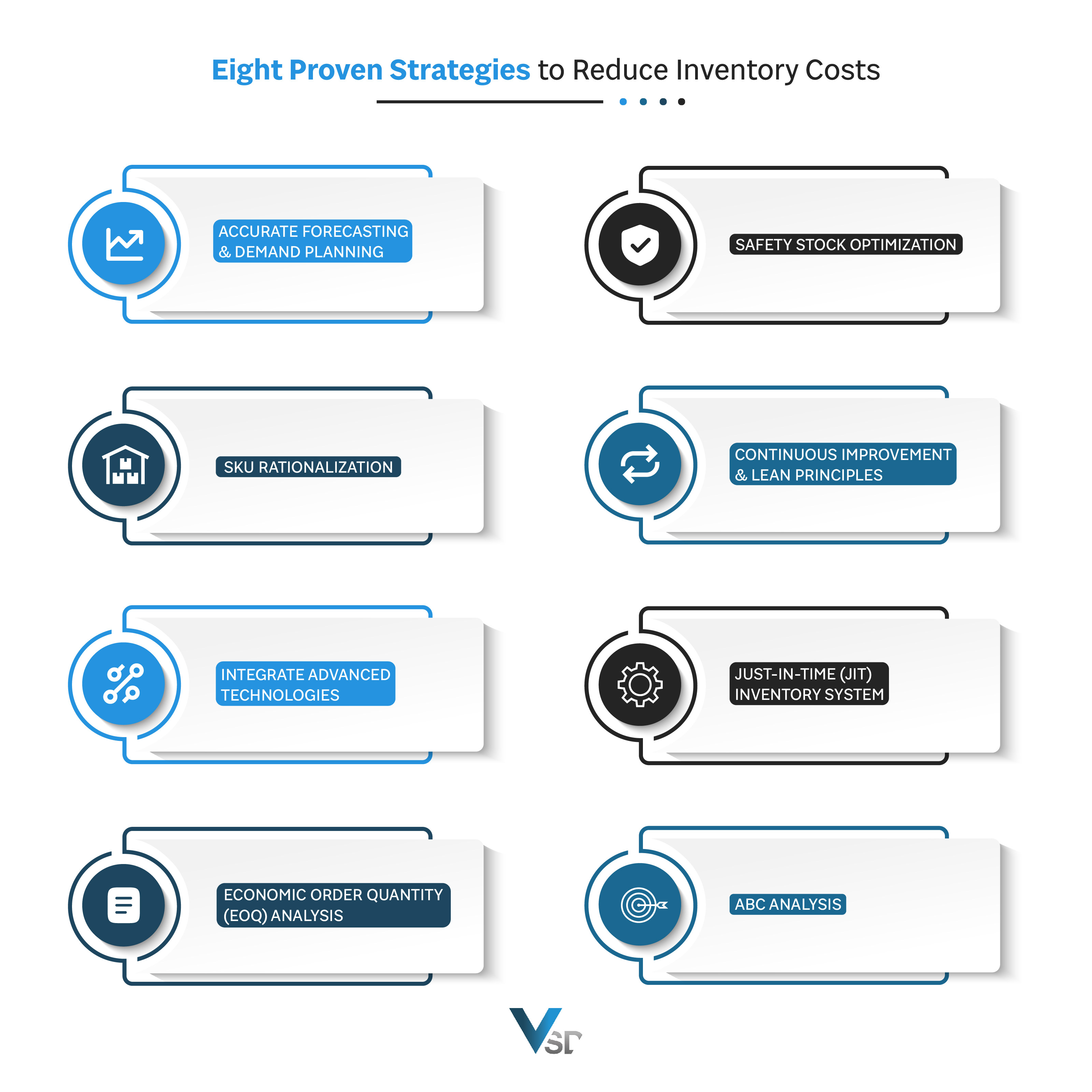

Eight Proven Strategies to Reduce Inventory Costs

Read ahead and avoid inefficient inventory practices that can lead to increased operational expenses, missed sales opportunities, and lost profits.

1. Accurate Forecasting and Demand Planning

One of the most crucial elements of inventory management is forecasting and demand planning. Accurate demand forecasts enable businesses to align stock levels with customer needs, reducing the risk of overstocking or running out of stock. Companies with accurate demand forecasting practices can reduce their overall supply chain costs by up to 15%, according to a report by APQC. Improving forecast accuracy can lead to reductions in both finished goods and raw material inventory. This underscores the value of investing in reliable forecasting tools and processes. To optimize forecasting:

- Use historical data and market trends to predict demand.

- Invest in forecasting software that analyzes large datasets.

- Continuously review and adjust forecasts based on real-time sales data.

2. Safety Stock Optimization

Safety stock serves as a buffer against uncertainties in demand and supply. While it’s essential for avoiding stockouts, excessive safety stock can tie up capital and increase carrying costs. Companies typically hold safety stock levels equivalent to 10-30 days of sales. The key is to optimize safety stock levels to balance the risk of stockouts with the cost of holding inventory. Best practices for safety stock:

- Regularly analyze demand variability and supplier lead times.

- Adjust safety stock levels during peak seasons or market fluctuations.

3. SKU Rationalization

Not all products are created equal. Some contribute more to your revenue, while others may simply take up space and capital. SKU, Stock Keeping Unit, rationalization involves periodically reviewing and optimizing your SKU portfolio to focus on higher-demand products, reducing complexity and cutting costs. Maximizing the number of units can lead to significant cost savings and improved operational efficiency by reducing inventory complexity and improving process cycle efficiency. Balancing the right number of SKUs is crucial, as too many can lead to inefficiencies, while too few can impact market competitiveness and customer satisfaction. Regularly reviewing your product portfolio ensures that you’re investing in the right items.

How to Rationalize SKUs:

- Regularly review your SKU portfolio to identify slow-moving or obsolete items.

- Focus on high-demand products that contribute the most to revenue.

4. Embrace Continuous Improvement and Lean Principles

Lean manufacturing principles like continuous improvement can lead to significant reductions in inventory levels and improved inventory turns. According to the Lean Enterprise Institute (LEI), businesses applying lean practices can experience a 25-75% reduction in inventory levels, which not only lowers costs but also accelerates production cycles.

Steps to apply lean principles:

- Eliminate wasteful processes that don’t add value.

- Continuously monitor and improve inventory workflows.

5. Integrate Advanced Technologies

Integrating advanced inventory management systems with your ERP or other enterprise systems can significantly enhance data visibility, decision-making, and overall efficiency. These systems allow for real-time tracking, automated reordering, and detailed analytics, which help businesses maintain optimal inventory levels, reduce carrying costs, and improve customer satisfaction.

For example, by utilizing an Enterprise Asset Management (EAM) system, companies can easily integrate their inventory management processes into a broader enterprise resource planning (ERP) framework, such as Microsoft Dynamics 365 Business Central. TAG EAM offers real-time data synchronization across all operational areas, enabling accurate and timely decision-making. It also provides predictive analytics and AI-driven insights, helping businesses forecast demand, prevent stockouts, and optimize inventory levels proactively.

Instant benefits of integrating advance tech:

- Real-time tracking and automated reordering.

- AI-driven predictive analytics for inventory optimization.

6. Just-In-Time (JIT) Inventory System

The Just-In-Time (JIT) inventory system is all about minimizing waste by ordering inventory only when it’s needed. This approach reduces storage costs and improves cash flow. However, it requires a reliable supply chain and accurate demand forecasting.

How to implement JIT:

- Establish strong supplier relationships.

- Use forecasting tools to ensure precise timing for orders.

This will avoid increased carrying costs and potential obsolescence.

7. Economic Order Quantity (EOQ) Analysis

Economic Order Quantity (EOQ) is a formula that calculates the optimal order quantity to minimize total inventory costs, including ordering and holding costs. By using EOQ analysis, businesses can find the perfect balance between order frequency and inventory holding. How EOQ works:

- Calculate EOQ using the formula: EOQ = √(2DS/H), where D is demand, S is the ordering cost, and H is the holding cost per unit.

- Use EOQ to determine the most cost-effective order quantity.

- Regularly update the EOQ calculation as costs and demand change.

8. ABC Analysis

ABC analysis categorizes inventory based on value and importance, allowing businesses to prioritize resources on high-value items. Typically, the top 20% of items (Category A) account for 80% of your inventory value, while Category C items may contribute less but still require management. Implementing ABC analysis:

- Classify inventory into A, B, and C categories based on value and turnover.

- Focus on optimizing inventory levels for Category A items.

- Review and adjust classifications regularly to align with business goals.

Maximize Profitability with Strategic Inventory Management

Effective inventory management is not a one-time task—it’s a continuous process that requires ongoing monitoring and adaptation. By implementing these eight strategies, your business can streamline inventory processes, reduce costs, and enhance profitability. The benefits are clear: better cash flow, increased customer satisfaction, and a competitive edge in the marketplace. Start optimizing your inventory today and watch your business thrive.

Optimize Inventory Costs with TAG

With TAG by Verosoft Design, you can integrate inventory management with your existing ERP systems, leverage advanced analytics for accurate demand forecasting, and optimize your stock levels in real-time. Learn more about how TAG can transform your inventory management by booking a discovery call today**.**